- #THREE WIRE BUTT SPLICE CONNECTORS HOW TO#

- #THREE WIRE BUTT SPLICE CONNECTORS MANUAL#

- #THREE WIRE BUTT SPLICE CONNECTORS FULL#

Cover with heat-shrink insulating tubing. Item listed is in new and excellent condition, without the original packaging.ģM Type UR-3 100 Pack Butt Splice Connector Red Phone Wire Crimp 19-26 AWG UG Modular IDC Telephone Conductor Data Signal Cable Squeeze Audio Connectors To join three wires together as you describe into a single circuit, just remove about 1-inch of insulation from each, twist them together, and solder the wires. Keep practicing your soldering technique until you are comfortable with it before you attempt it in the most confined spaces of a motorcycle.Up for sale is a pack of 100 Type UR-3 butt splice connectors that is manufactured by 3M. Then wrap it with electrical tape or shrink-wrap to prevent any accidental grounding against other wires or connectors. It looks ugly and will make the splice much larger once it’s covered with tape.Īfter the splice has cooled, trim any loose wires that could poke through the tape or shrink wrap. While you want the solder to cover most of the splice, try to avoid leaving big globs of solder on the joint. Touch the iron and solder to a few points on the splice to make sure it is uniformly spread throughout the wire strands. Capillary action plays an important role in distributing the solder throughout the splice. Holding the iron below the wires allows the heat to travel upwards while gravity pulls the molten solder down. Instead, allow the iron to heat the wire to the point that it melts the solder. When melting the solder to the wires, try not to touch the iron with the solder. This helps to spread out the heat when the tip touches the wires.

#THREE WIRE BUTT SPLICE CONNECTORS HOW TO#

Turn On: How To Install Switched Accessory Power To Your Motorcycleīefore touching the soldering tip to the wires, tin the tip by melting a small amount of solder on it. Anyone, even someone whose hands shake as much as mine do, can learn to solder with a minimum expenditure of blood and treasure.

#THREE WIRE BUTT SPLICE CONNECTORS FULL#

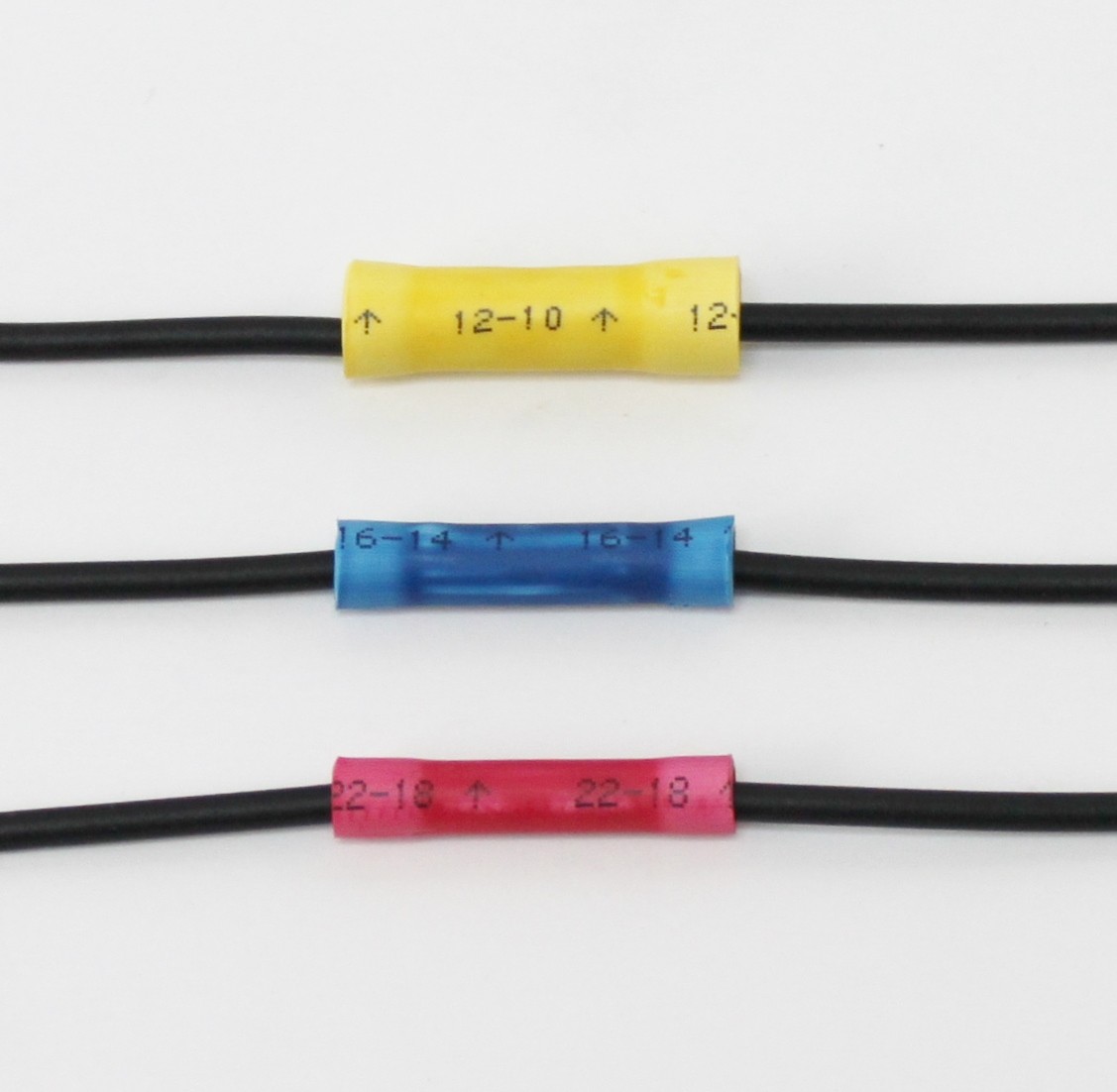

The source of the splicing fear usually is ignorance about soldering, which apparently many feel should only be done at midnight, during the full moon by a practitioner of the dark arts. Never fear, it is perfectly acceptable to splice wires if done correctly. However, soldering is also a great source of distress amongst novices. SVAAR 200pcs Butt Connectors Kit,Non Insulated Wire connectors Butt Splice Wire Connectors Electrical Crimp Butt Terminal 6 Gauge,8 Gauge,12-10,14-12,16-14,22-16 AWG Uninsulated Wire Ferrule Kit.

Soldering uses a hot iron to heat the wires to a temperature that will melt the solder, which when it cools takes care of the sturdy physical connection and the electrical conductivity. Mechanical connectors which physically clamp the wires together or to a common conductor are the easiest, but they take up more room and particular kinds are prone to failure. This can be done a couple of different ways. Wire splicing is the process of physically connecting two or more wires to make a mechanically strong, electrically sound path.

#THREE WIRE BUTT SPLICE CONNECTORS MANUAL#

While cutting your motorcycle’s wiring harness is not to be taken lightly and should only be attempted when you are certain as to which wires should be cut – by, say, obtaining the factory service manual – the process isn’t really that scary. 30190 Sealed Multiple Wire Connector, One 24-22 Ga. Upon a little digging, the bugaboo is usually fear of splicing wires into the bike’s harness. Butt Splice Connectors and Crimp Connectors offer a simple, effective way of completing a wide range of electrical wiring projects.

Time and again, I’ve had people tell me that they are afraid to modify their bike’s wiring harness to install a new accessory.

0 kommentar(er)

0 kommentar(er)